About Us

Our Goals

Mission & Vision

Our Commitment

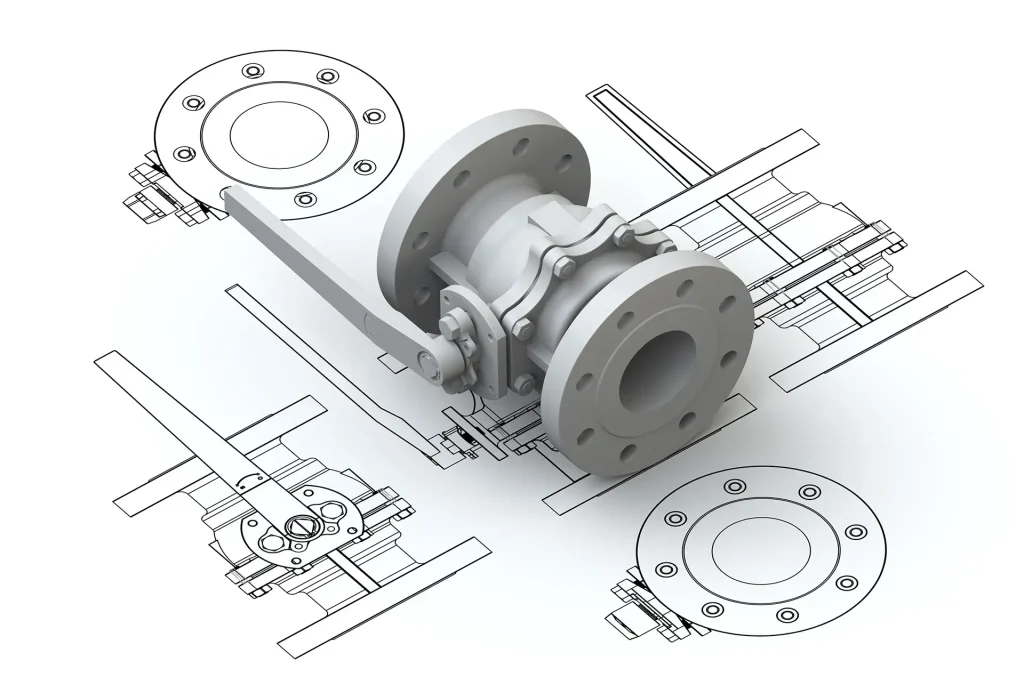

To provide superior valve solutions that exceed customer expectations through innovation, quality, and exceptional service.

Our Vision

To be the leading provider of valve products, setting industry standards for quality, reliability, and customer satisfaction.

Our Goals

Mission & Vision

Our Commitment

To provide superior valve solutions that meet or exceed customer expectations through innovation, quality, and exceptional service.

Our Vision

To be the leading provider of valve products, setting industry standards for quality, reliability, and customer satisfaction.

Who We Are

At Jordan Valves & Controls, we are committed to providing our customers with the best solutions for their specific applications. Our team works closely with you to ensure the right product is chosen for your operational needs, delivering reliability and efficiency across all industries. We’re not just about products, but about ensuring you have the optimal solution for every challenge.

Why Us

Choosing Jordan Valves & Controls means partnering with a team that delivers products and tailored solutions that meet or exceed your needs. We bring unmatched expertise and industry-leading products to ensure your operations run smoothly. Our commitment to quality, personalised service, and deep understanding of the pharmaceutical, water supply and general industries set us apart. With us, you’re getting a supplier, and a trusted partner focused on your success.

Who We Are

At Jordan Valves & Controls, we are committed to providing our customers with the best solutions for their specific applications. Our team works closely with you to ensure the right product is chosen for your operational needs, delivering reliability and efficiency across all industries. We’re not just about products, but about ensuring you have the optimal solution for every challenge.

Why us

Choosing Jordan Valves & Controls means partnering with a team dedicated to delivering not just products, but tailored solutions that meet your exact needs. We bring unmatched expertise and industry-leading products to ensure your operations run smoothly. Our commitment to quality, personalised service, and deep understanding of both the pharmaceutical and water supply industries set us apart. With us, you’re not just getting a supplier, but a trusted partner focused on your success.

Meet Our New Team

Meet the dedicated team behind Jordan Valves & Controls. Our experienced professionals come from diverse backgrounds, bringing together a wealth of expertise in valve distribution and industry-specific solutions. Each member is committed to delivering exceptional service and innovative solutions. Together, we are focused on building strong relationships and providing personalised support to help your operations run smoothly.

Greg Jordan

Company Founder

Ryan Warnock

Sales Manager

Simone Cardoso

Accounts/Sales Administration

Mark Owen

Director

Andrew Owen

Director

Our Commitment

To provide superior valve solutions that exceed customer expectations through innovation, quality, and exceptional service.

Our Vision

To be the leading provider of valve products, setting industry standards for quality, reliability, and customer satisfaction.

Our History

After serving as a drill sergeant and overseeing German POW’s returning home on liberty ships in WW2, Leonard D. Johnson started his career in the valve industry. Prior to starting United Valve, Leonard was in partnership with Gus Solberger in a company specializing in the buying and selling of surplus valves and fittings. During the late 40’s to mid-50’s, the government was disposing of huge amounts of unused surplus valves, flanges, and fittings stockpiled first for World War II and later for the Korean conflict. As a WWII veteran, Leonard was eligible to bid on and purchase these items. In 1961, after 10 years in the partnership, Leonard took a portion of the inventory and started United Valve.

A Few Highlights

3.2 million+

Estate planning docs

amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

2 million +

Businesses

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

20+ years

Leading industry

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

In those days, typical deliveries for modification orders were four to six weeks, due to the size of the orders. Comparatively, today’s modification work deliveries run one to two weeks. Some of the key customers during that era were Gulf Supply Co., the Wallace Company, Zidell Explorations, Grant Supply, and Tyler-Dawson.

In 1978, Leonard’s son Greg joined the business after a five-year stint outside of the valve industry. That same year, United Valve moved from its east Houston location to new facilities in the city of South Houston.

Coinciding with this move, the last bits of surplus valve inventory were sold or scrapped, and the initial valve sales era for United Valve came to an end. By this time, the core business was 98% valve modification, a trend that was to continue for the next 20 years.

1960s and 1970s – Adding Valve Repair and Modification

As the sixties rolled along, repair and modification operations began to eclipse the sale of valves as the prime profit generator for the company. During this period, Leonard’s wife, Wilmogene, and his eldest son Joel, began working for the company, making it a true “mom & pop” valve shop.

In 1967, United became an authorized Crosby relief valve repair center. A mobile unit for in-plant repair work helped usher in more and more industrial valve repair business. The company continued to expand in 1968 with the addition of a second facility located in Texas City, TX. Some of the key Texas City customers at that time were the Texas City Refinery and Union Carbide.

The decade of the 1970s brought more change as the repair function began to be phased out in favor of a new business focus: modification of new valves for distributors and supply houses. This new focus grew rapidly as the boom of the 70s exceeded the delivery capability of domestic manufacturers for “special” valves. The distributors would generally just stock “vanilla” valves and have them re-trimmed, or have special facings or packing and gaskets added to meet customer requirements.

Late 1970s and 1980s – Adapting to Imported Valves

In the late 70’s, the steel valve business began perhaps its most dramatic metamorphosis, as a new entity, the imported valve, landed on the American industrial scene in force. In an ironic twist, it was the tremendous worldwide demand for U.S. manufactured valves that opened the door for the imports. Huge worldwide petrochemical and refining projects completely depleted the U.S. valve manufacturers’ production capacity and forced refiners to look elsewhere to meet domestic valve demand.

Valves from Italy, Eastern Europe, Japan, and Korea helped fill the gap. It didn’t take long for the U.S. consumers to become accustomed to the lower price of the imports. The low-priced imports spelled doom for the large, high-overhead, integrated U.S. manufacturers. The next ten years would see Crane, Lunkenheimer, Walworth, and Jenkins close their integrated valve plants.

These imported valves were rarely brought into the U.S. in anything other than standard trim, so United Valve benefited from the additional industrial valve modification work they created. During the early 80’s United Valve attained the first of its OEM modification authorizations. The number of authorizations would continually increase over the years.

In 2019, United Valve opened its Corpus Christi location. Initially designed for actuator maintenance and repair, the facility is actively being expanded and a wide range of equipment installed to meet the repair, testing and modification needs of customers in the area.

Almost 65 years later, United Valve remains committed to providing complete and quality valve services. Under the direction of Greg, Paula, and their daughter and son-in-law, Kelly and Matt Lovell, United Valve continues to grow while providing new service offerings, and unsurpassed customer service, to the companies in which they serve.

Our History

In 2004, the company moved into new facilities conveniently located on the Gulf Freeway, one of Houston’s major highways. The 40,000 sq. ft. facility only lasted a few years as the company moved up the street into a new 64,000 sq. ft. facility.

The 64,000 sq. ft. facility was soon outgrown as well, and a 40,000 sq. ft. dedicated repair and engineering testing building was completed in 2017, bringing the total facility capacity for industrial valve repair, modification, and testing to 104,000 sq. ft.

To further expand its rising and rotating valve repair capabilities, United Valve purchased the assets of GRS Services, a leader in repairing those uniquely designed valves based in Lake Charles. The grinding and machining equipment was moved from Louisiana and installed in the Houston plant.