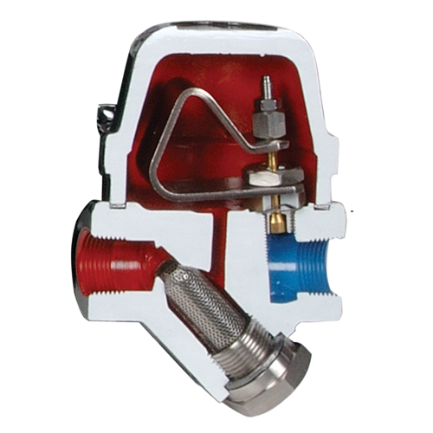

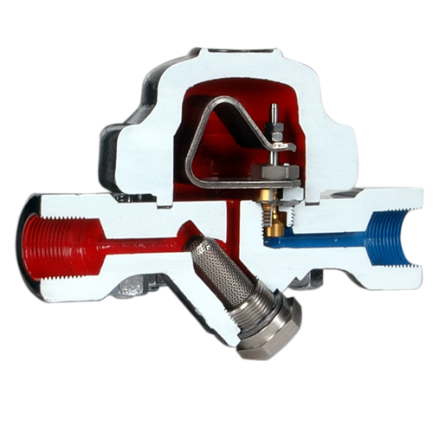

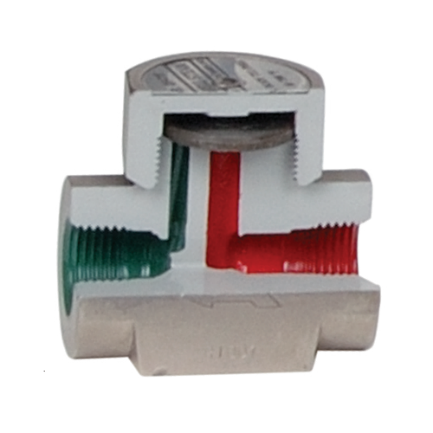

Delta Element / Bi Metallic Steam Traps

Steam traps that will provide years of trouble-free service with no live steam loss. The Delta Element trap can operate in applications with constant back pressure of up to 70% of inlet pressures.

– Long-term, trouble-free service due to single blade element, stainless steel internals, built-in strainer and check valve

– Only 30-40% of total pressure drop occurs over seating surface resulting in long valve life

– Problems due to cyclic discharge are eliminated with modulating discharge

– High cold discharge capacities provide fast start-up capabilities

– Excellent heat transfer and minimum corrosion by continuous air and CO2 venting

Steam Traps

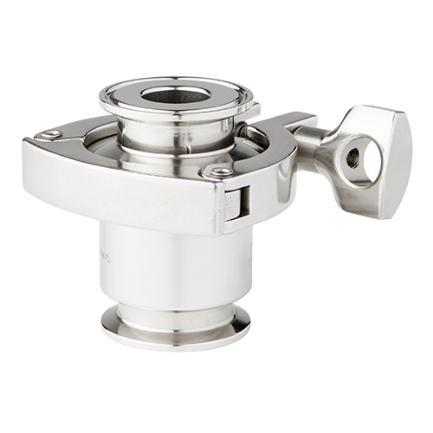

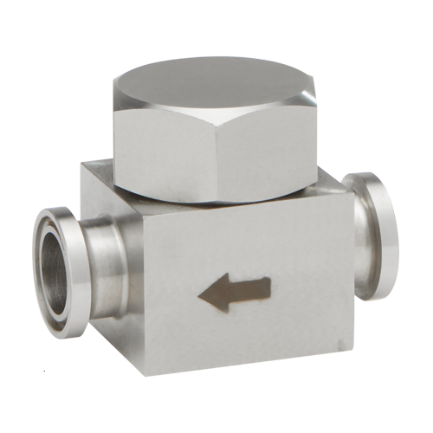

Along with the Delta Element steam traps, Bestobell also offers thermodynamic disc traps, sanitary clean steam traps and capsule traps.

Bestobell offers two types of disc traps: The DT711 with working pressures up to 711 psi and the DTCS which is a non-sanitary trap. The BTCS Series is a sanitary steam rap designed specifically for clean steam systems. There are two types of capsule traps – a stainless steel and a forged carbon steel that are ideal for harsh environments.

Inverted Bucket Traps

The inverted bucket trap is a simple design that has a unique leverage system that multiples the force provided by the bucket to open the valve against pressure.

Inverted bucket traps rely on the density difference between steam and water to drain condensate as it forms. An inverted bucket floats in condensate that surrounds the bucket. As the bucket moves up and down in the condensate, a linkage connected to the bucket closes or opens a discharge valve trapping the condensate or allowing it to escape.

The inverted bucket trap has only two moving parts – the valve lever assembly and the bucket. That means no fixed points, no complicated linkage, nothing to stick, bind or clog.

Float & Thermostatic Traps

When steam pressure may vary from maximum steam supply pressure to vacuum, float & thermostatic traps are your most energy-efficient choice. If you need performance, dependability and long life to trapping services requiring continuous drainage with high air venting capacity, we can help.

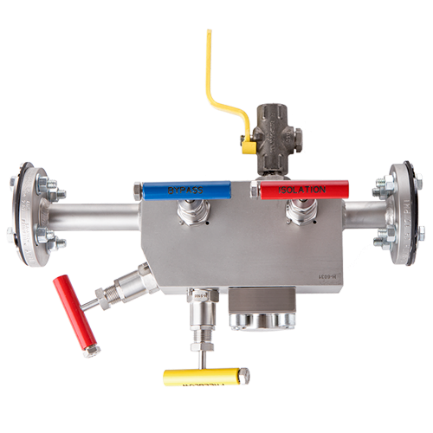

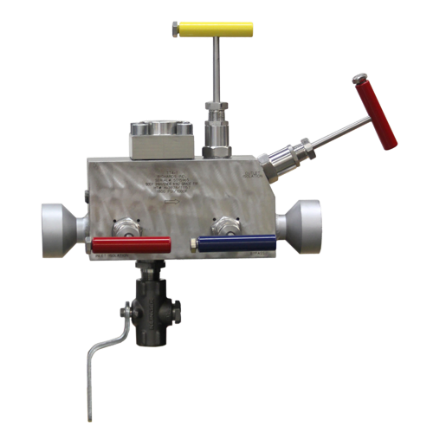

Total Traps

A line of compact, thermodynamic style steam trap stations for saturated steam designed to efficiently discharge condensate on applications with working pressures up to 2000 psig (138 bar) and temperatures up to 1000°F (538°C).

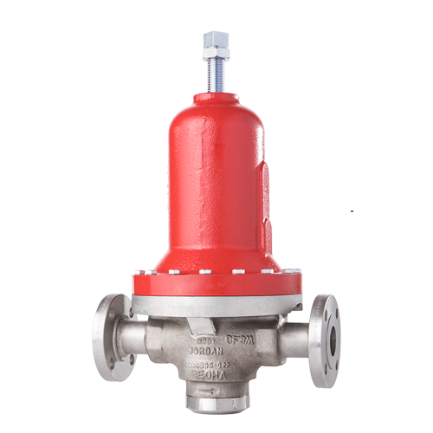

Accessories

Specialized accessories are offered to maximize the efficiency of your systems including pressure regulators, steam detectors and y-type strainers.

Capsule Traps

Specialised accessories are offered to maximize the efficiency of your systems including pressure regulators, steam detectors and y-type strainers.