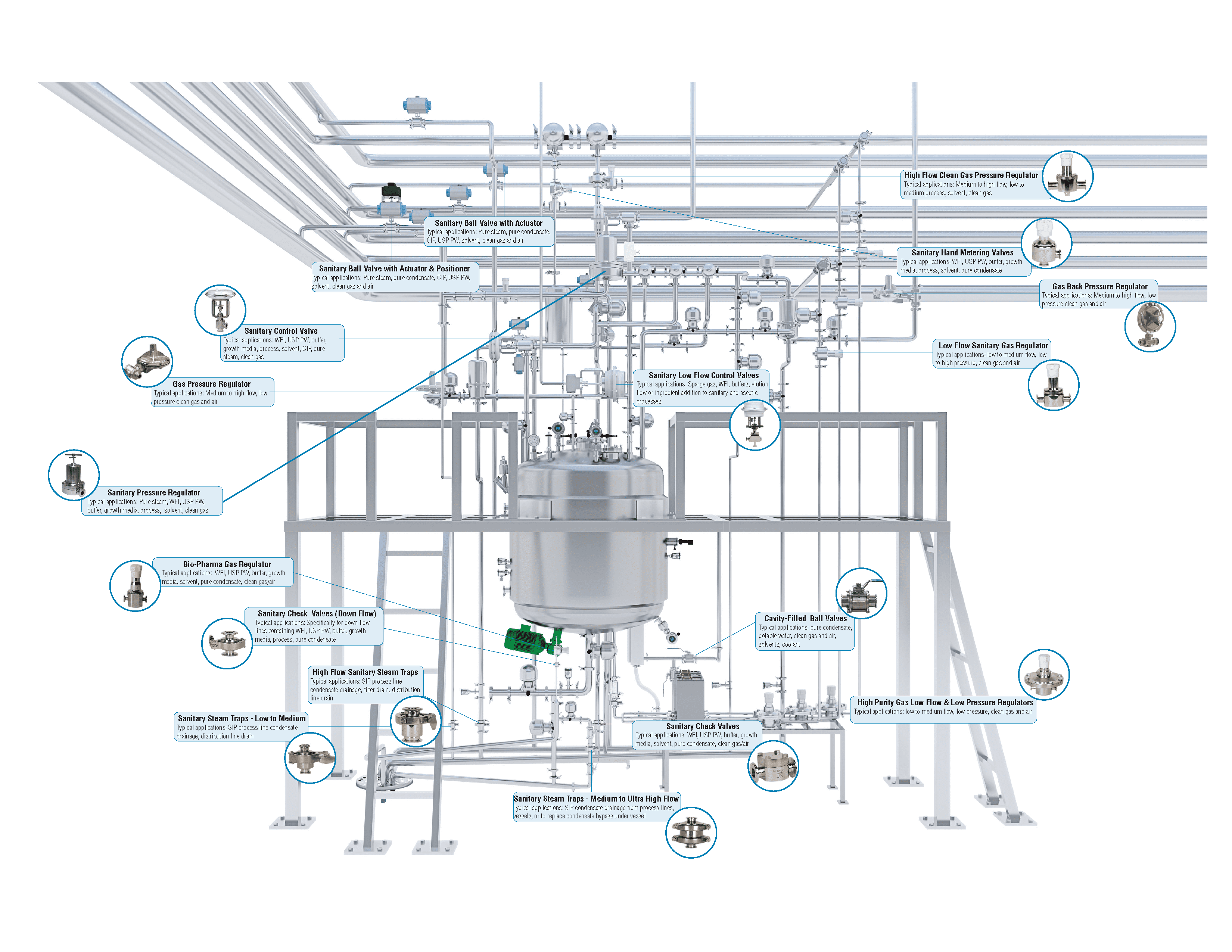

Steriflow Valves in Bioreactor Processing

Unmatched Expertise & Product Range

Process engineers and researchers depend on Steriflow Valve for our comprehensive range of sanitary

products, designed to meet the diverse fluid control needs in biopharma processing. Our products offer

precise flow and pressure control, suitable for both upstream and downstream bioprocessing applications,

including usage with Water for Injection (WFI), clean process gases, steam, and for Clean-in-Place (CIP)/

Steam-in-Place (SIP) processes. Our experienced engineers collaborate with you to identify the most

effective fluid control solutions for your specific applications. Discover the versatility of our valves in

various stages of the bioreactor process.

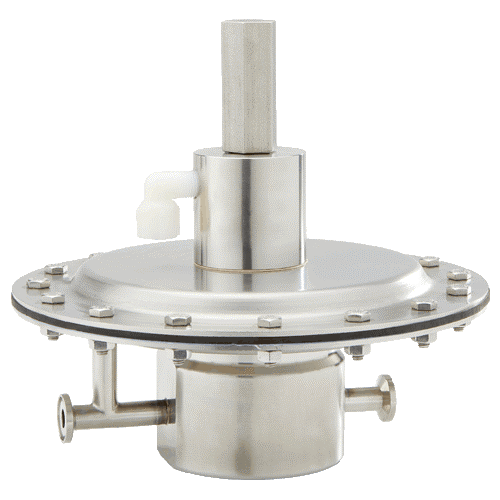

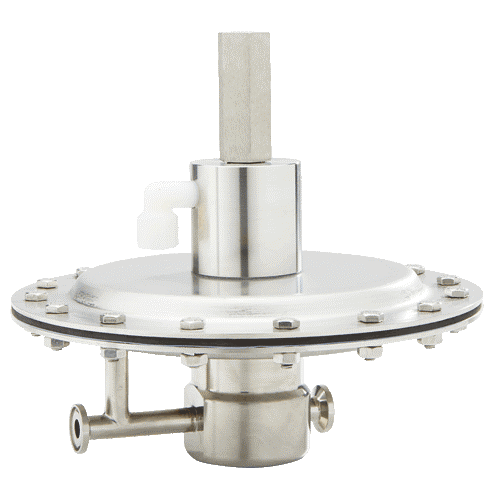

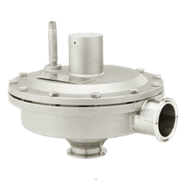

Sanitary Pressure Reducing Valves

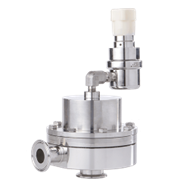

Sanitary Back Pressure Regulators

Sanitary Safety Relief Valves

The SSRV Sanitary Safety Relief Valves are designed to relieve over-pressure upset in hygienic and aseptic process and clean utility systems.

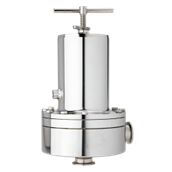

Clean Compressed Air & Gas Pressure Reducing Valves & Accessories

Clean Compressed Air & Gas Back Pressure Regulators & Accessories

Pharma clean compressed air and gas, back pressure regulating valves, 1/4″ – 3/4″ (DN8 – DN20), NPT, tri-clamp, weld ends, very low to medium flow, manual or air augmented, Jorlon™ lifetime diaphragm warranty.

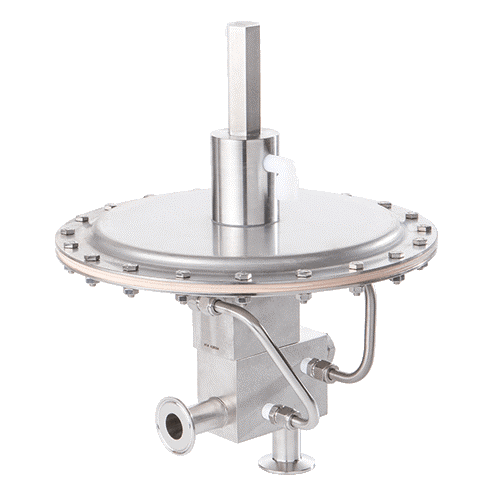

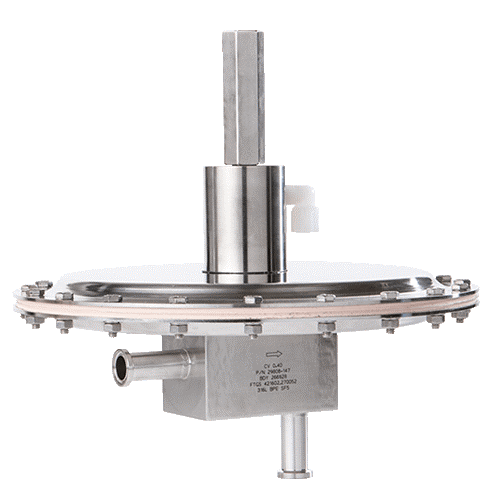

Steriflow’s clean compressed air and gas regulator product line offers some industry firsts, and is the most reliable and complete product application in existence. From sterile gas blanketing for stainless and single use vessels size 2L and larger, to bioreactor sparge or incubator regulation and high flow for air drying after sanitization, our BPRV range has all of your applications covered.

- Standard gas regulator flow range that range from 2L/min at 1 psi (70 bar) to 8000L/min at 75 psi (5,17 bar)

- Blanketing gas regulator flow ranges from 2L/min at 1/2″ w.c. (1.25 mbar) to 8000L/min at 5 psi (0,35 bar)

- Lifetime warranty on our Jorlon PTFE diaphragm

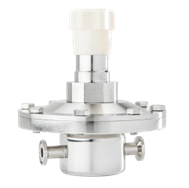

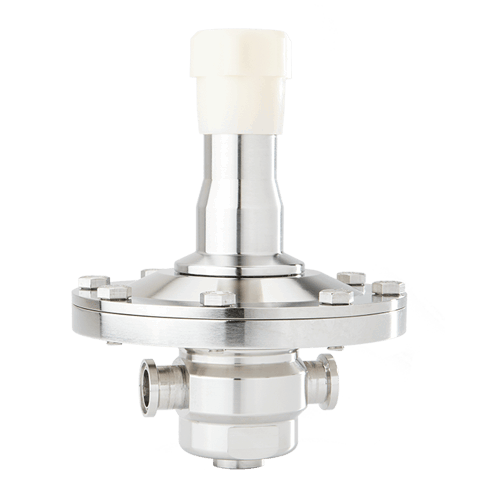

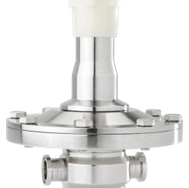

Sanitary Low Pressure Blanketing Regulators

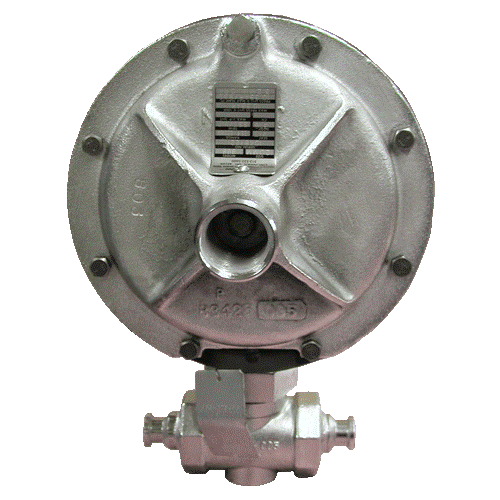

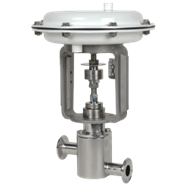

Sanitary Control Valves

Pharma process and clean utility control valves and positioners, 1/2″ – 3″ (DN15 – DN80), tri-clamp or weld end connections, very low flow to high flow, manual and automated, with Jorlon™ lifetime diaphragm warranty.

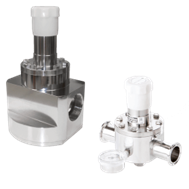

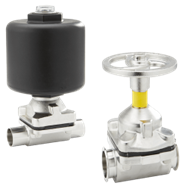

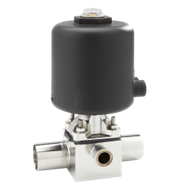

Sanitary Diaphragm Valves

Steriflow Valve now offers sanitary diaphragm valves. They are available as manual or air actuated forged 2-way or cast 2-ways, ported and tandem valves, barstock zero static T-block, point of use T-block, divert tank bottom and custom block body valves.

Clean Steam Traps & SIP Accessories

Clean steam traps and accessory devices for process SIP and distribution line condensate removal, 1/2″ – 2″ (DN15 – DN80), tri-clamp, weld end or NPT connections, low flow to very high flow, all with low subcooling.

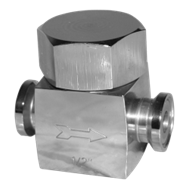

Sanitary Check Valves

Pharma process check valves, 1/2″ – 3″ (DN15 – DN80), for process vertical up-flow or down-flow (drain), and horizontal installation, floating disc design (no spring or sliding stem).

Food & Beverage Regulators & Control Valves

Our valves are used throughout the food & beverage industry in a wide variety of manufacturing areas for such applications as protecting steam and utility systems, and accurate flow control for a wide variety of gases, liquids and slurries.

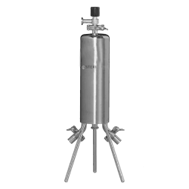

Sample Coolers, Sample Valves & Accessories

Pharma shell and spiral tube heat exchangers and sample valves for collection of clean steam and hot WFI samples, two styles for permanent mount (standard and removable shell) and a unit for mounting on a trolley.

Sight Glasses & Sight Glass Windows

Pharma process and clean utility sight glass and sight glass windows, 1/2″ – 4″ (DN15 – DN100) tri-clamp tubular sight glass, 1/2″ – 6″ (DN15 – DN100) sight glass windows, all certified borosilicate glass.

Sanitary Ball Valves

Three piece, full bore sanitary ball valves, low ferrite 316L, 1/2″ – 4″ (DN15 – DN100), TFM seats (cavity and non-cavity) and seals, for pharma clean steam, air and gas, acids and pneumatic conveyance of pharma powders.

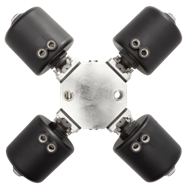

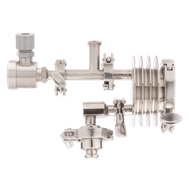

Clean Gas Distribution Manifold

Clean process gas distribution manifold with single inlet and six or twelve valve distribution points, tri-clamp or NPT connections.